ข้อมูลทางเทคนิค

TECHNICAL INFORMATION

ELECTROPOLISHING

FINISHING FOR THE FOOD INDUSTRY

MEETING INDUSTRY STANDARDS FOR SANITATION IN THE FOOD INDUSTRY

HOW THE FOOD INDUSTRY BENEFITS FROM ELECTROPOLISHING

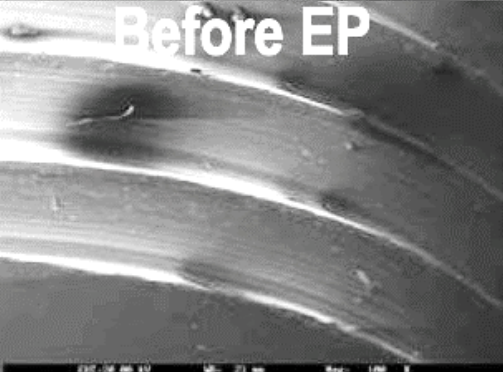

In the world of food service equipment manufacturing, corrosion resistance and cleanability are key. Electropolishing helps insure that both of these requirements are met. When a part is electropolished, the microscopic high points of the surface are removed at a faster rate. Sometimes referred to as “surface leveling,” electropolishing smoothes part surfaces, giving food particles and bacteria less places to harbor or stick to.

According to research done by the USDA’s ARS (Agricultural Research Service), electropolished surfaces perform better up against mechanically polished surfaces in terms of bacterial biofilm buildup in theory because of the electrochemical nature of the electropolishing process and the fact that bacteria are negatively charged. Electropolishing to a smoother surface ensures that there is less build-up in the first place and the products are easier to wipe down and quicker to clean at the end of the day.

Among many other finishing Treatments – electropolishing has proven to be the most effective in preventing harmful contaminants from forming on products’ surfaces

At the same time electropolishing enhances the chromium to iron ratio on the surface and restores the passive layer which makes the stainless standup longer to corrosive conditions. It’s no wonder many food service equipment manufacturers use electropolishing as a final finishing step in their process.

FOOD PROCESSING AND PACKAGING : Food processing and packaging parts must be highly sanitary for the applications in which they’re used

THE BENEFITS FROM ELECTROPOLISHING

- INCREASED CORROSION RESISTANCE

- REDUCED BUILDUP OF BACTERIAL BIOFILMS

Before and After

“ DURATRAY choose electropolishing as a final finishing step in our process for HYGIENIC area“

Loading and deflection characteristics